1. Automatic Powder Coating Machine Price and Key Components

An Automatic Powder Coating Machine comprises a robotic spray system, conveyor belt, curing oven, powder recovery unit, and control panel. These systems use electrostatic charging for precise powder application, ensuring uniform coverage. High-end models integrate IoT sensors for real-time adjustments. Understanding automatic powder coating machine price requires evaluating these components’ quality and automation levels.

2. Applications of Automatic Powder Coating Machines

Ideal for automotive (body panels, wheels), aerospace (engine parts), and appliance industries, automatic systems handle high-volume production. They excel in coating complex geometries like HVAC ducts or bicycle frames, delivering durable, corrosion-resistant finishes.

3. Cost Analysis of Automatic Powder Coating Machines

Automatic powder coating machine price ranges from 50,000to500,000. Entry-level models (50k–150k) suit SMEs, while large-scale industrial systems (200k–500k) include advanced recovery and AI-driven controls. Energy-efficient ovens and powder recycling can reduce long-term costs by 25–40%.

4. Operating an Automatic Powder Coating Machine

Pre-clean surfaces via sandblasting. Program robotic arms for consistent spray patterns (30–100 kV voltage). Set curing ovens to 350–450°F for 10–30 minutes. Monitor powder flow rates (5–20 kg/hour) via the control panel. Regular maintenance prevents downtime.

5. How to Choose an Automatic Powder Coating Machine

Prioritize throughput: 100–500 parts/hour systems cost 80k–250k. Check compatibility with epoxy, polyester, or hybrid powders. Opt for stainless steel recovery filters and ISO-certified suppliers. Ensure 24/7 technical support for automatic powder coating machine price negotiations.

6. Safety Measures for Automatic Powder Coating Systems

Install explosion-proof ventilation to manage combustible dust. Use grounded gloves and NIOSH-approved respirators. Regularly inspect robotic arms and electrical wiring. Store powders below 70°F to minimize fire risks.

7. Cost-Efficiency of Automatic Powder Coating Machines

Automated systems reduce labor costs by 60% and material waste by 90% via precise application. IoT-enabled machines optimize energy use, cutting power bills by 30%. Higher initial automatic powder coating machine price is offset by 3–5-year ROI in mass production.

8. FAQs About Automatic Powder Coating Machine Price

Q: What factors affect automatic powder coating machine price?

A: Automation level, conveyor length, and recovery efficiency impact costs.

Q: Can automatic systems replace manual labor entirely?

A: Yes—robotic arms ensure 24/7 operation with minimal human intervention.

Q: How to maintain an automatic powder coating machine?

A: Clean filters weekly, calibrate sensors monthly, and replace nozzles annually.

Q: Are used automatic powder coating machines cost-effective?

A: Refurbished systems (30k–120k) suit budget-limited buyers but require thorough inspection.

Q: Do automatic machines support custom coatings?

A: Advanced models allow programming for metallic, textured, or anti-graffiti finishes.

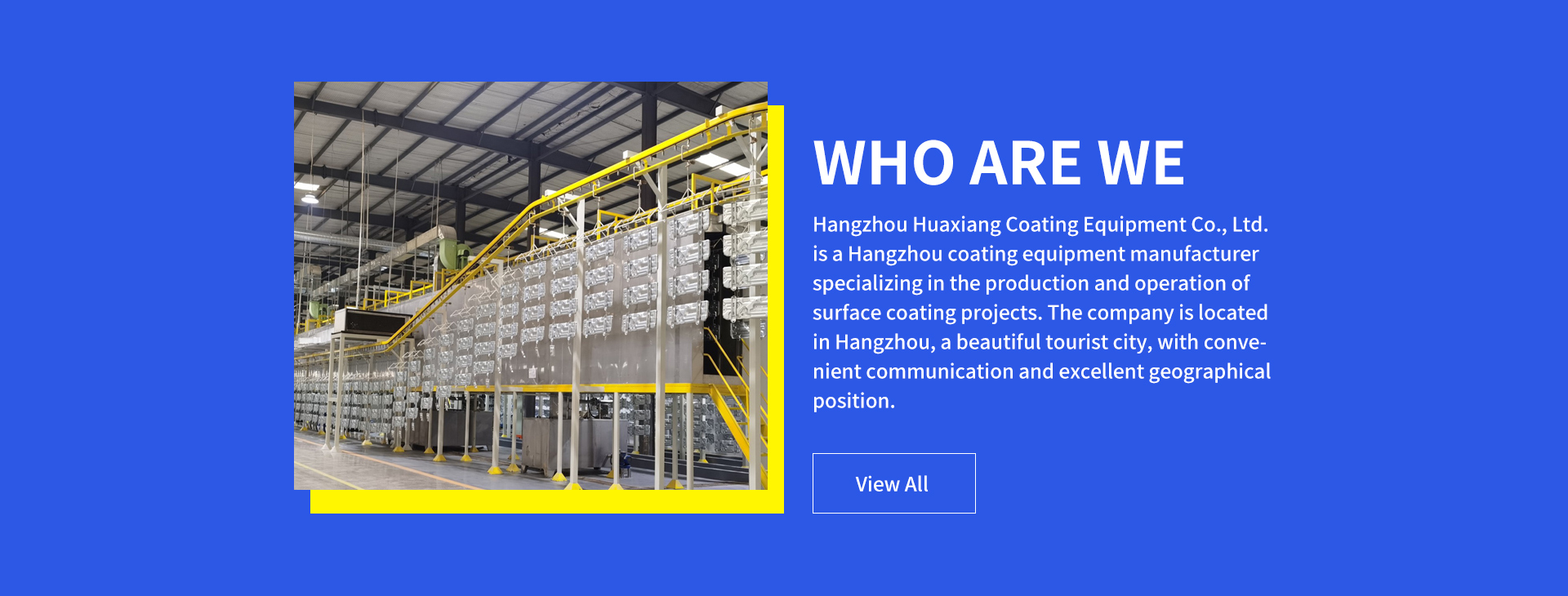

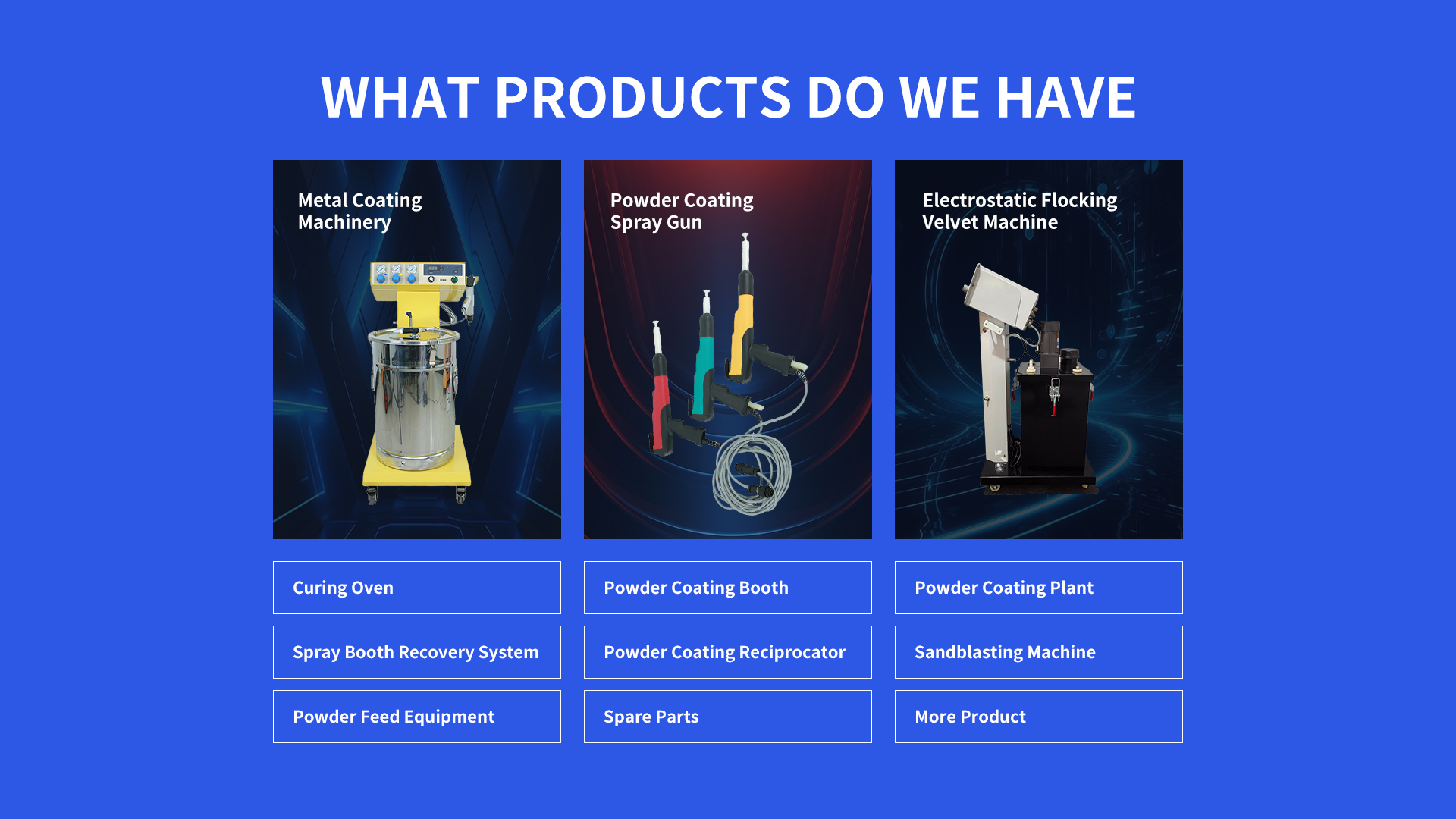

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com