1. Homemade Powder Coating Spray Booth Overview and Components

A Homemade Powder Coating Spray Booth is a cost-effective enclosure designed to contain overspray during powder application. Key components include a metal or wood frame, ventilation fans, filters (e.g., HEPA or fiberglass), lighting, and a grounded workspace. DIY builders often repurpose materials like PVC pipes or plywood to reduce costs.

2. How a Homemade Homemade Powder Coating Spray Booth Works

The Homemade Powder Coating Spray Booth uses airflow generated by exhaust fans to pull powder overspray through filters, preventing airborne particles. Grounded surfaces ensure electrostatic adhesion of powder to the workpiece. Proper lighting illuminates the coating area for precision, while filters trap reusable powder for minimal waste.

3. Factors Affecting Homemade Powder Coating Spray Booth Costs

Material quality (e.g., steel vs. plywood), booth size, and ventilation power impact costs. A basic DIY spray booth costs 100–500, while advanced setups with industrial-grade fans and filters reach $1,000. Repurposing household items (e.g., box fans) cuts expenses by 50%.

4. Applications of Homemade Powder Coating Spray Booths

Ideal for small workshops, automotive enthusiasts, and hobbyists coating bike frames, tools, or furniture. Homemade spray booths handle low-volume projects, providing a controlled environment for durable, professional-grade finishes.

5. How to Choose a Homemade Powder Coating Spray Booth Design

Assess workspace size: compact designs (4x4 ft) suit garages. Prioritize fire-resistant materials for safety. Ensure airflow rates (100–300 CFM) match powder volume. Opt for removable filters for easy cleaning.

6. Maintenance Tips for Homemade Powder Coating Spray Booths

Clean filters weekly to prevent clogging. Inspect electrical connections for grounding issues. Replace damaged fan blades or worn seals. Store the booth in dry conditions to avoid rust or warping.

7. Customizing a Homemade Powder Coating Spray Booth for Factory Needs

Scale designs for larger parts by extending frame dimensions. Add multiple exhaust ports for high-volume airflow. Integrate IoT sensors to monitor air quality or humidity. Use modular panels for easy disassembly and reconfiguration.

8. FAQs About Homemade Powder Coating Spray Booths

Q: Is a homemade powder coating spray booth cheaper than commercial models?

A: Yes—DIY booths cost 70–90% less than commercial units ($5,000+).

Q: How to ensure proper ventilation in a homemade spray booth?

A: Use inline fans with 200+ CFM ratings and position exhaust ducts away from work areas.

Q: Can I customize a homemade powder coating spray booth for large parts?

A: Yes—expandable frames and adjustable lighting accommodate oversized items.

Q: What materials are safest for DIY spray booths?

A: Fire-retardant plywood or metal sheets minimize combustion risks.

Q: How often should I replace spray booth filters?

A: Replace fiberglass filters every 20–30 uses; washable HEPA filters last 6–12 months.

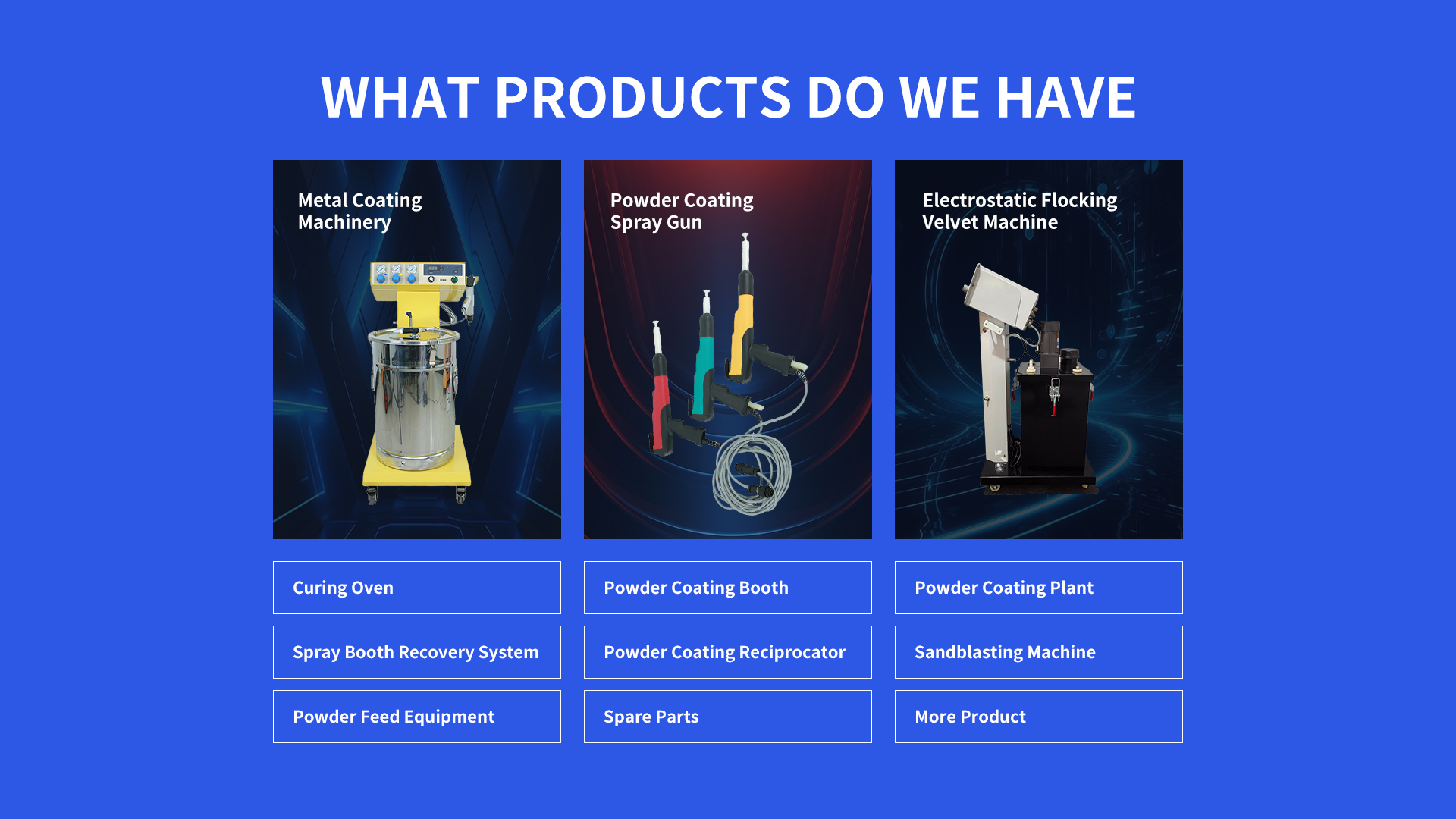

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com